Quality control process

Incoming Quality Control (ac)

Ensure that all raw materials meet st&ard specifications & conduct quality checks before production. Any materials that do not meet requirements should be promptly addressed or retumed to the supplier.

In-Process Quality Control (IPQC)

Conduct periodic quality checks at every key stage of production to ensure that the manufacturing process adheres to established quality st&ards.

Finished Product Inspection (FQC)

After the production of finished products, a final quality inspection is conducted. This includes functional testing, appearance inspection, & dimensionalmeasurement to ensure that the products meet all technical specifications.

Equipment & Process Control (EPC)

Maintain the stability of production equipment & process parameters by ensuring regular maintenance & calibration,to prevent product quality issues caused by equipment failures.

Teaching&Training (T&E)

Ensure that production & quality control personnel receive adequate training to underst & product st&ards & quality control procedures. thereby reducing the likelihood of human errors.

Data Analysis & Feedback (DAF)

By collecting & analyzing production data, customer feedback, after-sales service data.& more, identify potential quality issues & take measures to improve products & processes.

Laboratory Testing

Laboratory testing: Rigorous testing under laboratory conditions, including sensitivity, linearity, response time, temperature and humidity effects, etc.

Strength Testing

Ensure the strength after welding to guarantee structural stability and safety.

Continuity Testing

Check the electrical performance of the encapsulated chip to ensure there are no breaks or failures.

PresSure Testing

Ensure there are no microcracks in the encapsulated chip, guaranteeing its reliability in high voltage environments.

Leak Testing

Measure theleakage ofthe encapsulated sintered product to ensure its airtightness and long-term reliability.

Performance Testing

Simulate the use of oxygen sensors in actual vehicles to ensure their performance meets the requirements.

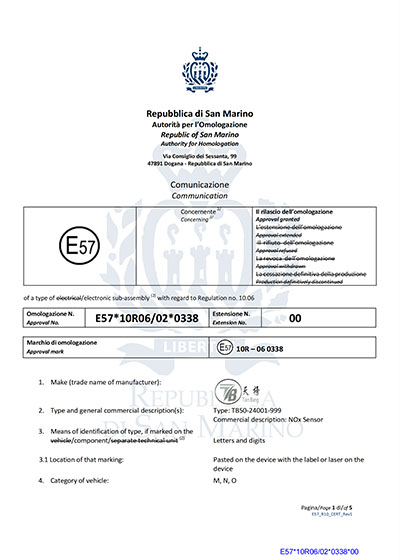

Quality certification

Quality is our core competitiveness. TIANBANG Automotive has passed IATF16949 quality management system certification, and all products strictly comply with E-mark and CE certification standards. We use advanced quality inspection systems to ensure that every product shipped meets the highest reliability and accuracy requirements.

CONTACT US

It is important for us to communicate with you and respond to your needs. Do you have any questions requests or comments?